The answer to this question, seemingly uncomplicated, aroused and still arouses much debate. To make things clear, we start to describe what are the technologies available. The world of the elevation is divided into two types of technologies:

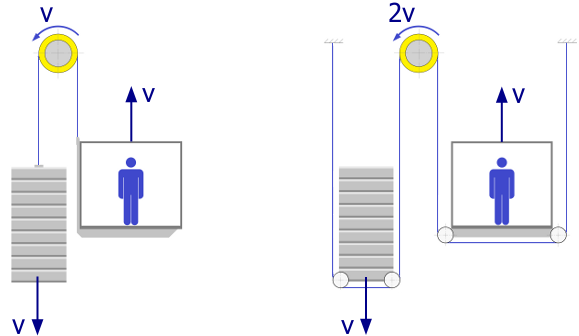

- Traction Technology: it is an engine hoist (geared or gearless), positioned on top of the elevator shaft (with direct or indirect system), which moves a pulley and rope connected to a cabin (carrying people / goods) and a counterweight. There are other solutions where the motor can also be placed at the bottom of the pit, on the car or even on the counterweight.

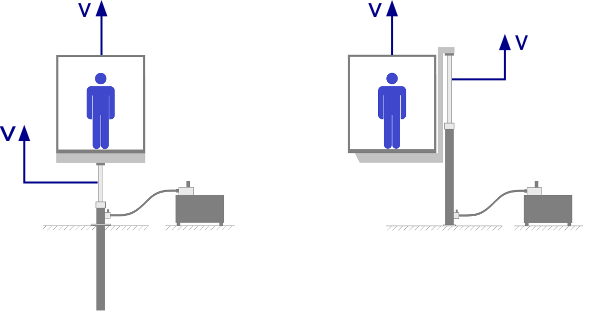

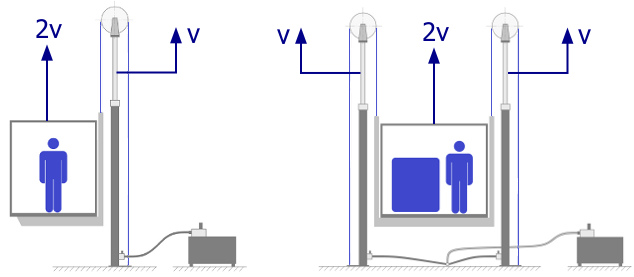

- Hydraulic Technology: it is a hydraulic control unit (equipped with mechanical or electronic valve, pump and motor) connected, through a hydraulic hose, to a piston (or more) that pushes the cab from the bottom to the top through oil or fluid. The thrust can be directed centrally, direct and indirect side. The latter is the most used.

Once described in broad terms the two technologies, the correct question that you must ask the user is: which technology to choose? Well, dear user I inform you that a clear and official answer to this question in not available yet, and I invite you to be wary of those who argue that the solution with traction technology is better than hydraulic or vice versa!

The criteria to select one of those two technologies are influenced by several reasons. By not dwell in stressful technicalities, from our point of view, the main criteria are:

- Type of Destination: Residential, Private, Public, Industrial, Elimination of Architectural Barriers.

- Analysis of Traffic: how many people move and number of travel per day.

It is our duty to point out that the hydraulic technology has two technical limitations of application:

- Travel: the maximum travel cannot be higher than 26 m.

- Speed: The maximum speed is 1 m/s.

These limits are, however, not so penalizing, since they are two specs that are commonly required for applications like buildings over 7/8 floors or High-rise.

How much does an elevator cost?

A insidious and tricky question. Our experience taught us that the cost of a lift is evaluated considering three parameters:

a) Cost of Material and Installation

b) Maintenance Fee for at least five years (preferably 10 years)

c) Cost of spare parts for at least five years (preferably 10 years)

There are many manufacturers and installers that use very simple techniques: the selling price of the material and installation very competitive price of the rent very high maintenance, spare parts sales price of extremely high (compared to the actual value of the material itself). It is obvious that, with this strategy, the user is easy to fall into a trap, bewitched by the "price" and the recognition of the "brand", without taking into account the factor "b" and "c".

This is why we urge you to carefully evaluate all three parameters and always request to the supplier all the information needed to calculate the real cost of a lift.